Metal Fabrication

Fabrication

Sheet metal fabrication is a manufacturing method that involves cutting and bending sheets of metal to form different shapes. Sheet metal fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness.

Available materials for sheet metal

Below is a list of our standard available metals for sheet metal fabrication.

| Aluminum | Stainless steel | Mild steel | Copper |

| 6061-T6 | 303 | 1018 | C110 |

| 5052 | 304 | ||

| 5754 | 316L |

Available sheet metal fabrication processes

| Name | Description | Allowable sheet thickness |

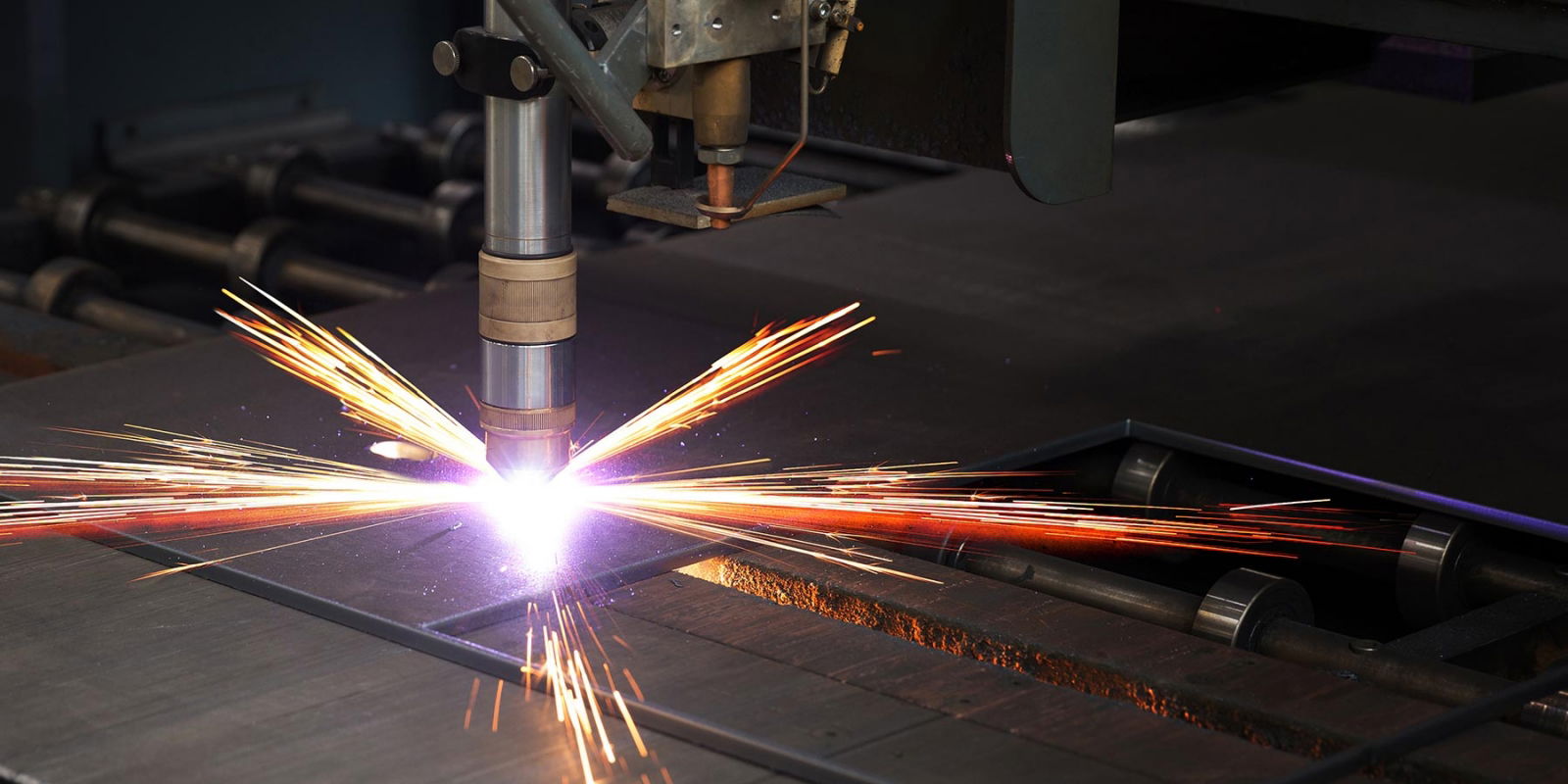

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 0.5 - 25 mm ( Dependent on Material Type ) |

| Water Cutting | A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance | A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water, or a mixture of water and an abrasive substance |

| Bending | This manufacturing process uses dies to produce a U-shape, V- shape or channel shape along a straight axis in ductile materials. | 0.5 - 10 mm ( Dependent on Material Type ) |

Tolerances for sheet metal fabrication

The table below summarizes the standard tolerances of the parts produced by Tuff Cor.

| Feature | Tolerance |

| Cutting feature | ± .00787’’ (0.2 mm) |

| Bend angle | ± 1.0° |

| Bend to edge | +/- 0.010” (0.254mm) |

Tig Welding

TIG welding, is an arc welding process that uses a tungsten electrode to produce the weld. The weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium) and a filler metal is normally used. TIG welding is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminium, magnesium, and copper alloys. The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quality welds. However, TIG welding is comparatively more complex and difficult to master and furthermore, it is significantly slower than most other welding techniques.

Co2 Welding

Co2 Welding is basically MiG/GMAW Welding. It is a fusion welding process where joining takes place by an electric arc shielded by co2 gas and electrode is consumable.

Upload files and configure parts to get a quote

Tuff Cor (Pty) Ltd will be able to help you with all your manufacturing and product development need through our in-house services and knowledge. We make use of our large network of reliable supplier for any service we do not have in-house.

Contact

- 57 Genl Van Reyneveld Street, Persequor, Pretoria, South Africa