Surface Finishing

Our surface finishing capabilities

Use Creative Product Solutions as your one-stop solution for both manufacturing and surface finishing of your custom CNC machined parts, reducing the risk of production.

Choose the right finish for your material

Different surface finishes can be applied to different materials. Find below a quick cheat sheet of surface finish and material compatibility.

| Name | Material compatibility | Rough price increase* |

| Smoothing | All plastics and metals | +10% |

| Bead blasting | All metals | +5% |

| Powder coating | All metals | +15% |

| Anodizing clear (type II) | Aluminum and Titanium alloys | +15% |

| Anodizing color (type II) | Aluminum and Titanium alloys | +20% |

| Anodizing hardcoat (type III) | Aluminum and Titanium alloys | +30% |

Our standard surface finishes

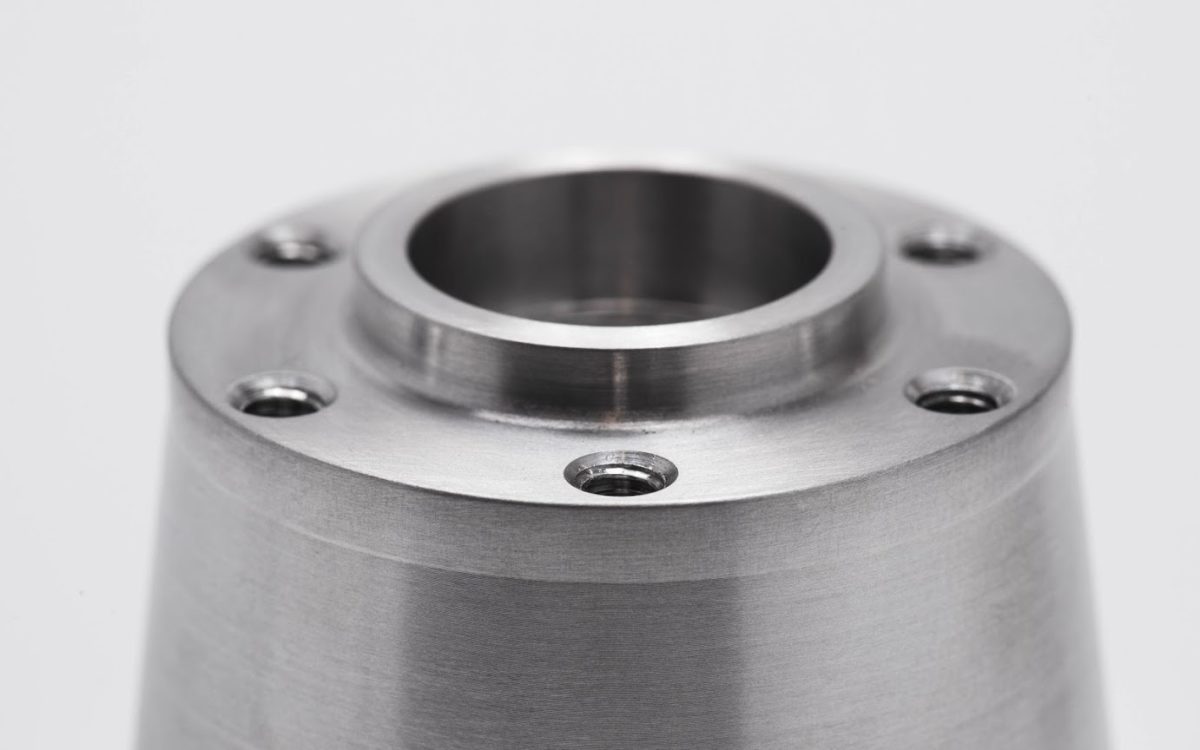

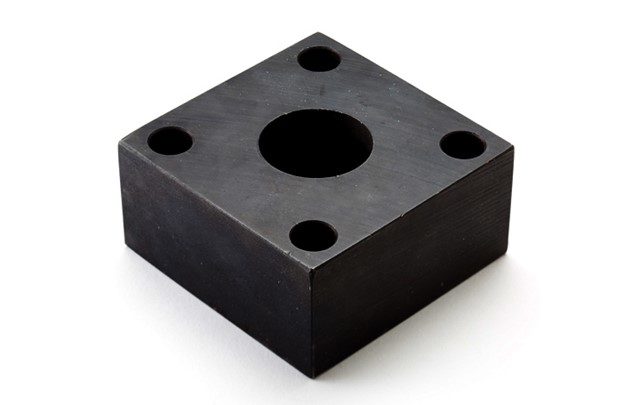

As machined

Our standard finish is “as machined” finish. It has a surface roughness of 3.2 μm (126 μin). All sharp edges are removed and parts are deburred. Tool marks are visible.

Smoothing

A finishing CNC machining operation can be applied to the part to reduce its surface roughness. The standard smoothing surface roughness (Ra) is 1.6 μm (63 μin). This can be decreased down to 0.4 μm (15.7 μin) upon request and on a case-by-case basis. Machine marks are less evident but still visible.

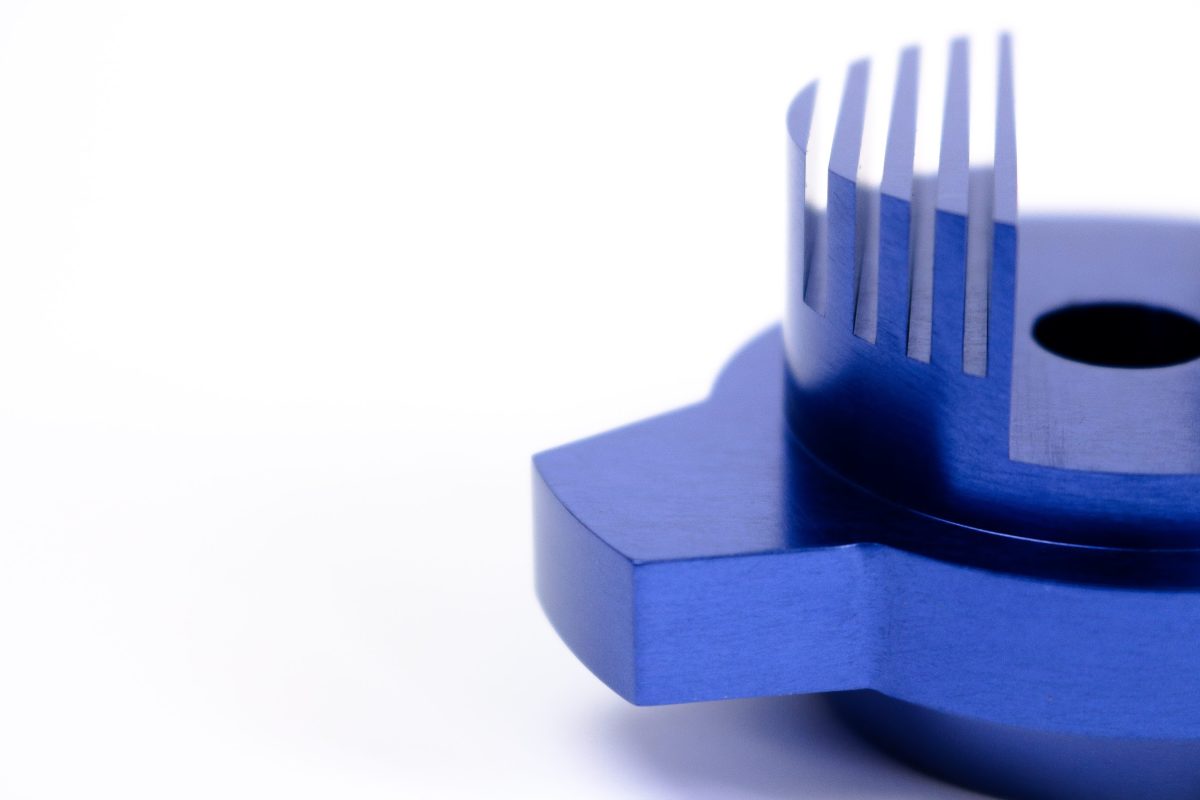

Anodizing color or clear (type II)

Type II anodizing is mainly used to produce parts with a uniform, aesthetically pleasing surface and provides good corrosion and limited wear resistance.

| Requirement | Specification |

| Thickness | 8 - 12 μm (clear), 4 - 8 μm (color) |

| Color | Black, clear or any RAL code or Pantone number |

| Part masking | Indicate masking requirements in technical drawing |

Anodizing hardcoat (type III)

Type III anodizing provides excellent corrosion and wear resistance, suitable for functional applications.

| Requirement | Specification |

| Thickness | 50 - 125 μm |

| Color | Black or clear |

| Part masking | Indicate masking requirements in technical drawing |

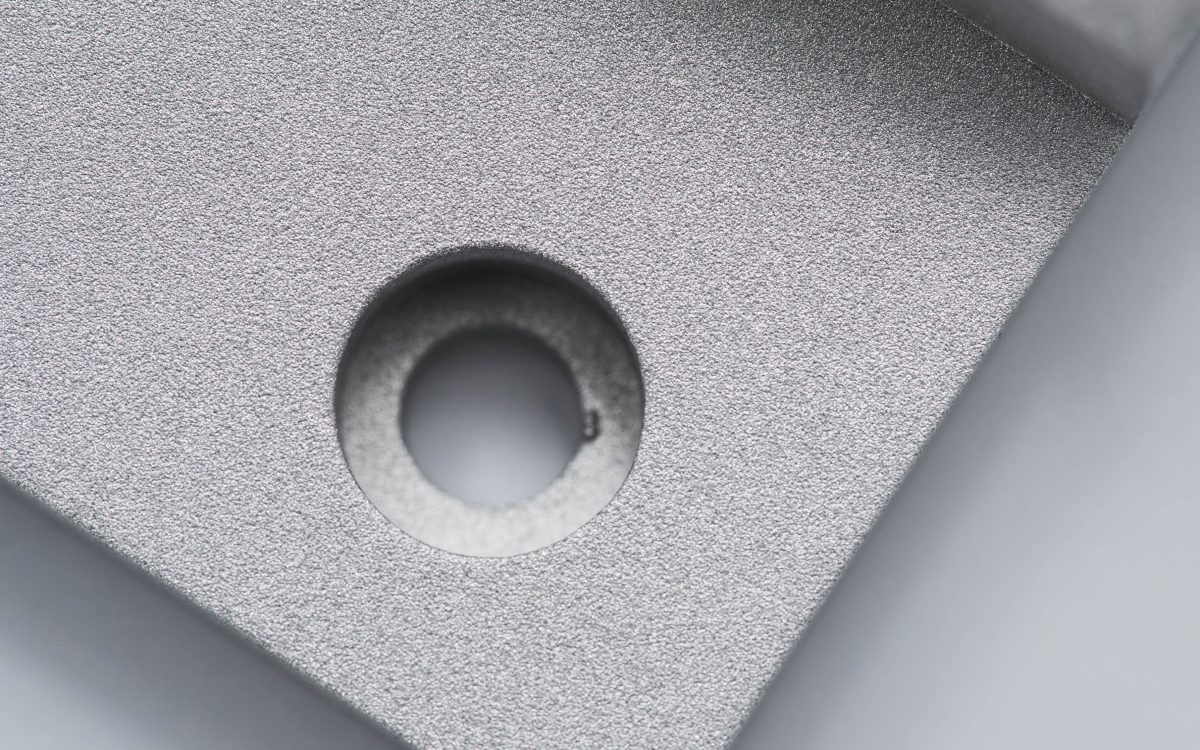

Bead blasting

Bead blasting adds a uniform matte or satin surface finish on a machined part, removing the tool marks. This is used mainly for visual purposes and comes in several different grits which indicate the size of the bombarding pellets.

| Requirement | Specification |

| Grit | #100, #120 and #150 |

| Color | Uniform matte of raw material color |

| Part masking | Indicate masking requirements in technical drawing |

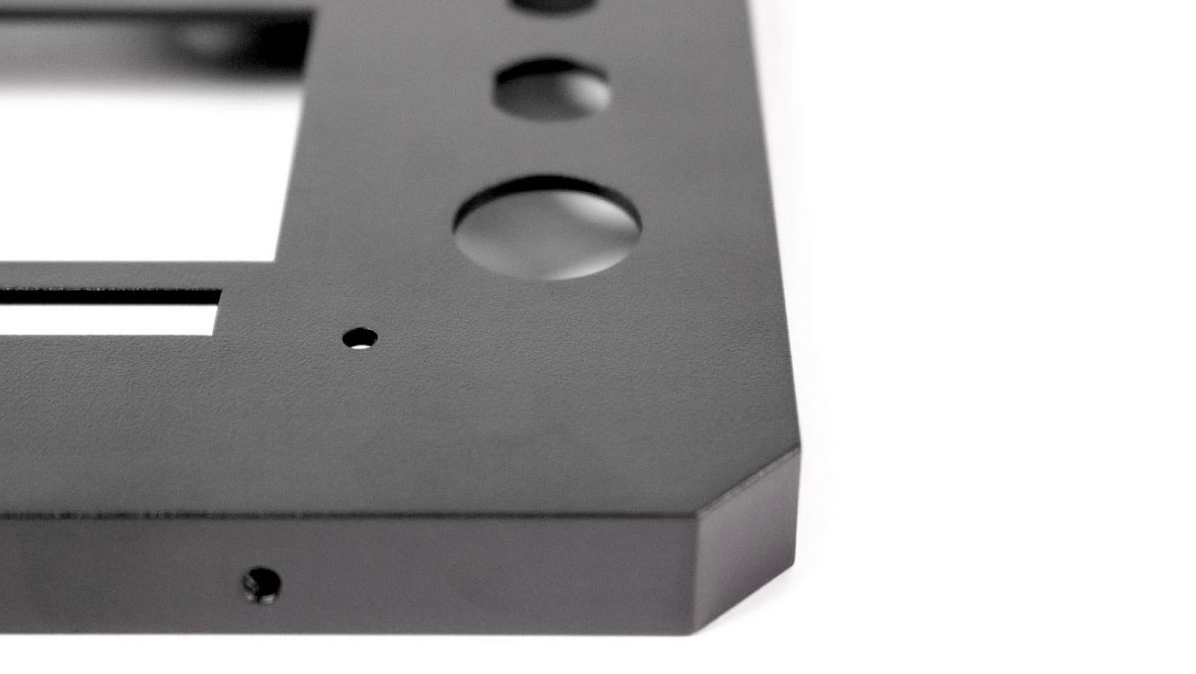

Powder coating

Powder coating is a strong, wear-resistant finish that is compatible with all metal materials and can be combined with a bead blasting to create parts with smooth and uniform surfaces and excellent corrosion resistance.

| Requirement | Specification |

| Thickness | 18 - 72μm |

| Color | Black or any RAL code or Pantone number. |

| Part masking | Indicate masking requirements in technical drawing. |

Electropolishing

Electropolishing is an electrochemical process used to polish, passivate and deburr metal parts. It is useful to reduce surface roughness.

| Requirement | Specification |

| Color | Natural metal color. |

| Part masking | Indicate masking requirements in technical drawing. |

Black oxide

Black oxide is a conversion coating used to improve corrosion resistance and minimize light reflection.

| Requirement | Specification |

| Color | Black |

| Part masking | Indicate masking requirements in technical drawing. |

Brushing

Brushing is produced by polishing the metal with grit resulting in a unidirectional satin finish. Not advisable for applications where corrosion resistance is required.

| Requirement | Specification |

| Surface roughness | 0.8 - 1.5 μm |

| Grit | #80-120 |

| Part masking | Indicate masking requirements in technical drawing. |

Upload files and configure parts to get a quote

Disclaimer

Tuff Cor (Pty) Ltd will be able to help you with all your manufacturing and product development need through our in-house services and knowledge. We make use of our large network of reliable supplier for any service we do not have in-house.

F.A.Q

What are surface finishing operations

What is surface finishing in engineering

Why do we need surface finishing

Surface finishing is essential for improving aesthetics, protecting the underlying material, and improving functionality. If you're considering using surface finishing on a project

Contact

- 57 Genl Van Reyneveld Street, Persequor, Pretoria, South Africa